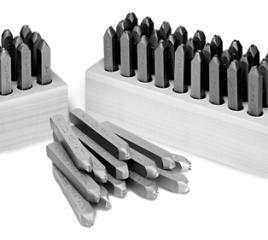

Steel Stamps, Steel Type, & Holders

GT SCHMIDT has been manufacturing steel marking tools since it first opened its doors in 1895. For over 125 years, we have supplied virtually every industry with the highest quality and most reliable steel stamps, steel type, die holders and type holders.

We offer a wide variety of steel marking tools for both manual and machine applications. We manufacture hand stamps and manual style straight type holders. If you are roll marking, press marking or rotary roll marking, we have the steel type, steel dies, machine style holders and support fixtures needed for your part marking application.

SEE ALL OUR STAMP, TYPE, DIE, AND HOLDER OPTIONS

General Steel Marking Information

GENERAL MARKING GUIDELINES: CHARACTER FACES, CHARACTER SIZE AND SPACING

Indented Characters

The character size should be determined by measuring the face of the tool, as indicated in the character sketches below. Sharp Face and Aerocut tools are measured at the apex of the engraved face. Flat Face and Outline style characters are measured to the outside edge or overall dimension of the engraved face.

Embossed Characters

These are the exception and are measured from the impression rather than the face of the die. The size is determined by the height of the impression at the point where the raised portion meets the background.

Debossed Characters

The size of a debossed character is measured at the point where the bevel of the male die meets the background.

GT SCHMIDT'S STEEL MARKING TOOLS ARE AVAILABLE IN ONE OF THE FOLLOWING FIVE FACES.

SHARP FACE

Sharp face characters use a sharp edge where the tool comes in contact with the part. A sharp face tool penetrates more easily than other styles.

AEROCUT FACE

The Aerocut engraved face produces a specially designed rounded face for marking impressions with minimum stress at the point of contact.

FLAT FACE

Flat face characters are used in order to produce a wider impression. This face is often used on brass or other nonferrous metals or when the impression is to be color-filled.

OUTLINE FACE

These have two sharp face lines to produce the double line impression of an outline character. This style is often used to emphasize trade names or designs.

AEROCUT DOT FACE

These faces have specially rounded interrupted faces for the lowest possible stress. They are recommended for high pressure fittings, aircraft and other parts where sharp tools might disturb the molecular structure of the metal.

CHARACTER SIZE AND SPACING

Determining Character Size Requirements for Your Mark:

There is a natural tendency to select a larger character size than required. This will result in a die that may be too long for the marking area or tonnage requirements may be increased unnecessarily.

Each letter or figure occupies a space as wide as it is high. Fractions (1/2, 1/4, etc.) are made with the characters in line - not above one another. A fraction will occupy space equal to letters or figures of the same character size.

For example, 1/8" characters are spaced 8 to the inch. Marking the word "TEMPERED" using an 1/8" character would occupy one inch. The same reading in 3/32" characters would yield a mark 3/4" of an inch long.

Where there is a specific requirement, our logotype, dies or type can either be extended for a large area or condensed to permit stamping the legend in a confined area.

STANDARD TYPE SPACING

Standard type spacing is easily determined. The blank is the same as the character size multiplied by the total number of characters in the reading. (i.e. If a 1/16" character is used, and eight character word will be 1/2" long.) Condensed and extended style characters will decrease and increase these measurements respectively.

STRAIGHT LOGOTYPE SPACING

Straight logotype spacing is determined in the same manner as the standard type spacing. Each character occupies an amount of space equal to the character size.

KNURL LOGOTYPE SPACING

Knurl logotype spacing is calculated the same way as straight logotype, except that a space equal to one half a character is added before and after the reading. Thus the knurl logotype blank is one character longer than a straight logotype with the same reading.

General Marking Guidelines

Depth of Engraving (GTS Standards)

| Character Size | Depth |

| 3/64" | .012" |

| 1/16" | .014" |

| 3/32" | .018" |

| 1/8" | .023" |

| 5/32" | .028" |

| 3/16" | .031" |

| 7/32" | .033" |

| 1/4" | .035" |

| 5/16" | .040" |

| 3/8" | .050" |

| 7/16" | .055" |

| 1/2" | .060" |

| 5/8" | .062" |

| 3/4" | .078" |

| 1" | .093" |

Extra Deep Engraving

Required when material is removed from a part after marking and an abnormally deep mark is required. Branding dies are engraved extra deep and with a flat face so the background of the hot die will not touch the material.

Controlled Depth Engraving

In some applications, engraving may be shallower than standard depth. Trademarks and other lettering layouts are often irregular, which can result in an uneven impression. By engraving all characters and border lines somewhat shallower, the die can “bottom” (that means the die will penetrate to the background so that the whole mark is uniformly deep.

Bevels

The angle or bevel of the sides of engraved characters can be variable depending on the specific application. However, most dies for marking mild steel are engraved with 45 degree bevels. Branding or embossing tools are cut with straighter sides and flat faces. Heavier bevels and extra deep engraving are sometimes specified for particularly tough marking jobs.

Pressure Requirements for Marking

Pressure to mark one Sharp Face character (in tons)

In order to estimate marking pressure requirements, multiply the single character tonnage by the number of characters to be marked. To mark half depth, multiply tonnage requirements by 0.75; to mark two times the depth, multiply the tonnage requirements by 1.33; to mark three times the depth, multiply tonnage requirements by 1.7.

| Character Size | Mild Steel | Soft Aluminum | Tool Steel | Character Depth |

| 1/16 | 0.25 | 0.15 | 0.38 | .003 |

| 3/32 | 0.5 | 0.3 | 0.75 | .004 |

| 1/8 | 0.75 | 0.45 | 1.13 | .006 |

| 5/32 | 1 | 0.6 | 1.5 | .007 |

| 3/16 | 1.88 | 1.13 | 2.82 | .008 |

| 1/4 | 2.1 | 1.26 | 3.15 | .010 |

| 5/16 | 3 | 1.8 | 4.5 | .013 |

| 3/8 | 4 | 2.4 | 6 | .016 |

| 7/16 | 4.75 | 2.85 | 7.13 | .016 |

| 1/2 | 5.7 | 3.42 | 8.55 | .017 |

| 5/8 | 7.5 | 4.5 | 11.25 | .020 |

| 3/4 | 9.25 | 5.55 | 13.88 | .020 |

| 7/8 | 11 | 6.6 | 16.5 | .020 |

| 1 | 13 | 7.8 | 19.5 | .020 |

STRAIGHT STEP TYPE

L = length

W = width

H = height

Hs = height from step to bottom of die

D = depth of step

Wb = overall width of blank

(L x W x H)

step: (Hsx D)

KNURL GROOVE TYPE

L = length

W = width

H = height

Hg = height is from the middle of the

groove to the bottom of the die

Wg = width of groove

D = depth of groove

A = angle

(L x W x H)

groove: (Hg x Wg x D angle: A)

KNURL STEP TYPE

L = length

W = width

H = height

Hs = height from step to bottom of die

D = depth of step

Wb = overall width of blank

A = angle

(L x W x H)

step: Hs x D angle: A)

LETTERING KNURL (ROUND DIE)

D = diameter

W = width

Db = diameter of bore

K = width of keyway

K/2 = depth of keyway

(D x W x Db x K x K/2)

need a custom solution?

Our in-house design and engineering department has a full range of services and support to ensure that your marking application is successful.

ADDITIONAL INFORMATION

Why GT SCHMIDT?

At GT SCHMIDT, we design, build, and implement marking solutions that help manufacturers leave a lasting mark on their products, their companies, and their industries.

Learn More About Us

made in usa since 1895

125 years of experience

installation & follow-up support