Nameplate Marking

WHY MARK A NAMEPLATE INSTEAD OF A PART?

There are many common reasons to mark a nameplate instead of a part. Sometimes directly marking a part is too difficult or not even possible. The part may be too large to bring to a marking system or the part's surface may be uneven or too fragile to mark. If your mark contains data or information that will change (lot codes, inspection dates, etc.), permanently marking the part directly would not be a good idea.

In these and many other situations, nameplate marking is a great solution. You get the usual, permanent mark from your marking system but get increased flexibility by putting it on a nameplate. The nameplate can be installed on your part and later removed when the information changes or needs to be updated. Additionally, nameplate marking is often much easier than marking a part directly, and with our nameplate marking solutions, the process can be done in bulk and aided by automation.

WHAT ARE SOME OF THE CHALLENGES IN MARKING NAMEPLATES?

Generally, nameplates are very easy to mark. But certain design qualities can make the process difficult.

If the nameplates are too thin (less than 0.020 inches thick), they may curl or deform during the marking process. They also may be too thin to be fed through a nameplate shuttlefeed. Similarly, if the nameplates aren't manufactured to close tolerances, nameplates can be difficult to clamp or feed.

The shape of a nameplate matters too. Rectangular nameplates in general are much easier to mark and feed than circular or oval-shaped nameplates. For these applications, a Pick-and-Place system is the only way to automate feeding.

WHAT ARE SOME BENEFITS TO MARKING NAMEPLATES?

There are several marking technologies capable of marking nameplates. Each have their own benefits and the best marking machine for you will depend on your nameplate marking application and goals.

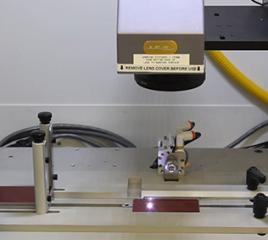

Lasers can be customized with different feeding systems. Not only can they mark letters and numbers, but they can also make data marks, logos, images, and more. They are also capable of marking nameplates that may be too thin or delicate for other marking technologies.

Pin markers can also be customized with different feeding systems. They mark very quickly and can mark letters, numbers, and data marks. Pin markers can make very deep marks that endure even the harshest of environments.

Traditional marking machines have different nameplate marking options. Generally, they're great when you need to make deep marks with the same information into a high volume of nameplates.

WHAT SHOULD BE CONSIDERED WHEN SELECTING A NAMEPLATE MARKING SOLUTION?

When selecting a nameplate marking solution, consider the following questions:

- How quickly do the marks need to be made?

- How many nameplates need to be marked every day?

- Are you marking a pre-printed silk screen nameplate or a blank nameplate?

- Will you only be marking text and other simple characters or do you need to mark images, logos, etc.?

- Overall, do you want a more aesthetically pleasing mark?

- How thick and rigid are the nameplates?

Your answer to these questions will determine which marking technology, accessories, and options are best for your application. To discuss your answers, call us at 847-647-7117, and we can help you find the right marking solution for your nameplate application.

need a custom solution?

Our in-house design and engineering department has a full range of services and support to ensure that your industrial automation project is successful.

ADDITIONAL INFORMATION

Why GT SCHMIDT?

At GT SCHMIDT, we design, build, and implement marking solutions that help manufacturers leave a lasting mark on their products, their companies, and their industries.

Learn More About Us

made in usa since 1895

125 years of experience

installation & follow-up support